Road and other width restrictions may mean that similar or identical wheels can not be dualled together.

Stocks have designed a system enabling wheels of different diameters and widths to be dualled together when the two tyres have a similar static loaded radius (SLR).

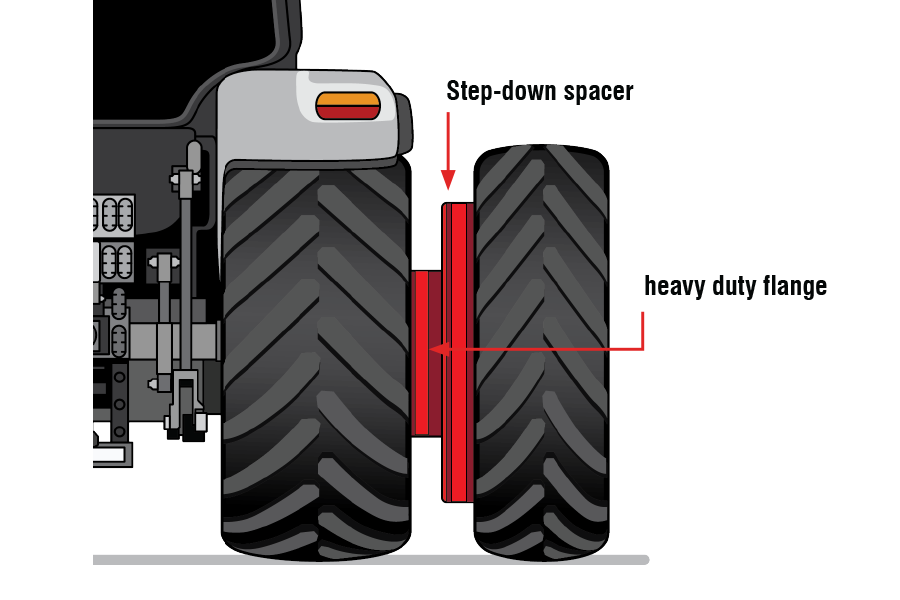

Stocks take a rim with one diameter and fit it with a spacer band of a different diameter to enable the step-up/step-down wheel to fit to the different size vehicle wheel.

A heavy duty flange welded between the rim and the spacer band takes up the difference in diameters and provides strength and reinforcement.

The key features and benefits seen with standard Stocks dual wheels also apply the stepped duals. Standard clamps, hooks and eye nuts and ribbed spacer bands are used throughout.

KEY FEATURES

-

High quality rims

-

Heavy duty flange

-

Continuously machine welded power rail

-

High tensile steel threaded rods

-

Hardened and tempered hookends

-

Ribbed spacer bands

-

Easy to fit and tension wheel clamps

-

Any brand/any size of tyre

-

Colour matched pain

BENEFITS

-

Reduced width - for applications constricted by overall width

-

Improved versatility

-

Useful flotation and traction at modest cost

-

Decreased compaction - improved soil structure, drainage and plant establishment

-

Reduced deep wheelings - fewer expensive remedial deep cultivations

-

Reduced wheel slip - reduced tyre wear and soil smearing

-

Reduced tyre pressures - improved ride and bigger tyre footprint

-

Increased stability - increased safety on hillside work

-

Double the tyre beads - reduced chance of tyres spinning on the rims of high horsepower tractors

STEP-DOWN DUALS

This is the most popular stepped dual and generally uses a bigger diameter wheel with a narrower tyre as the dual.

Step-down duals are a great way to benefit from dual wheels if overall width is a concern. A perfect solution for applications constricted by overall width, and whilst designed for any machine, this design is particularly suited to combines.

For example, a 340/85R48 dual tyre alongside a 520/85R38 tractor tyre will reduce the overall vehicle width to match an implement or make roadwork easier, or a 520/85R42 dual tyre alongside a 710/70 R 38 tractor tyre offers less expensive dualling than using two 710 tyres.

STEP-UP DUALS

If the tractor is fitted with relatively large diameter wheels and narrow tyres, a smaller diameter wheel with a wider tyre of a matching SLR can be fitted as the dual. Care must be taken to ensure that the vehicle wheel is strong enough to support the extra leverage with the stepped dual fitted.

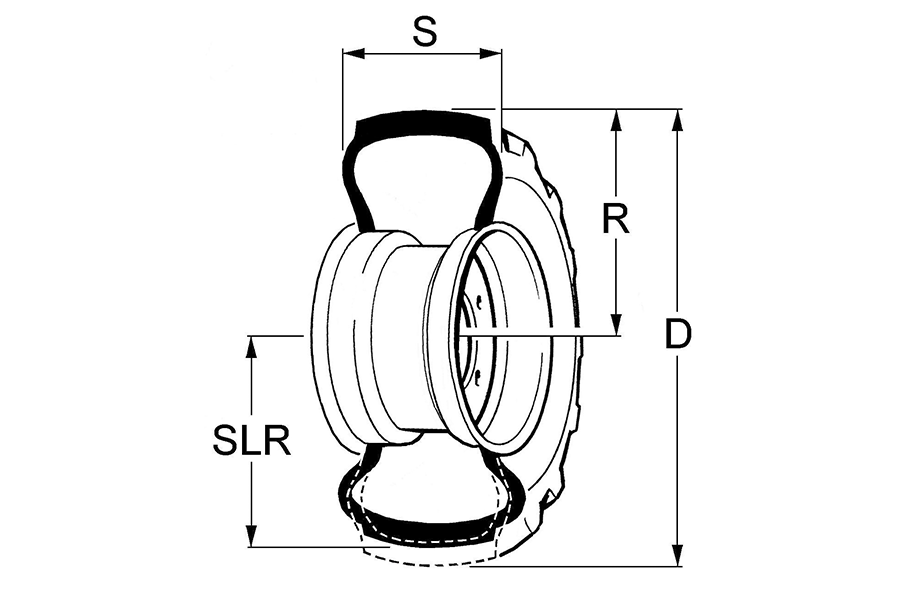

STATIC LOADED RADIUS (SLR)

When designing a step-down/step-up dual wheel for either a tractor or combine, the SLR (static loaded radius) figure is key. SLR - is the distance from the centre of the axle to the ground, with the tyre deflected under load.

The SLR or static loaded radius is the important figure to refer to when selecting any dual wheel product.

Ideally the SLR of both tyres will be the same, or the dual tyre slightly less than the vehicle tyre, but it may be acceptable to have the dual tyre slightly larger than the vehicle tyre.

SLR - Static Loaded Radius

S - Section Width

R - Radius

D - Overall Diameter (2xR)

DUALS SUITABLE FOR COMBINES

Step-down duals are particularly suited to combines. Most large combines are fitted with a 32” diameter tyre of various widths and profiles and the majority of these have a very similar SLR.

A standard 520/85R38 tractor tyre will work as a dual alongside most of these 32” combine tyres and provide useful flotation and traction at modest cost, and without putting massive strain on the combine axle and hubs.

VALVE GUARDS

On forestry and other specific wheels, Stocks can fit a variety of valve guards for optimum valve protection.

PAINT

All wheels are colour matched if requested and any paint type can be specified.

StocksAg Wheels are painted to match the colour of your tractor

EVERY ENQUIRY BEGINS WITH TYRES

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp