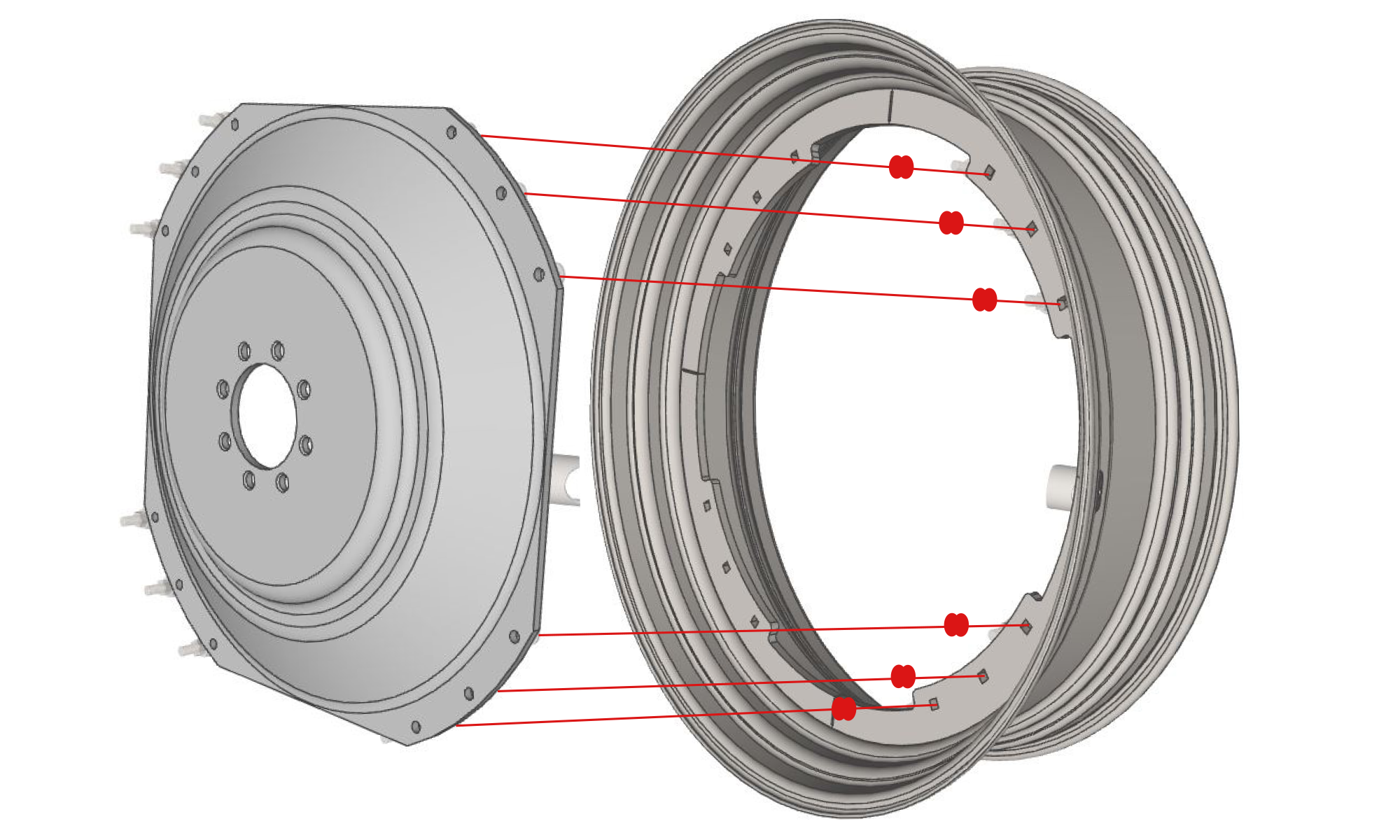

Adjustable centre wheels offer a range of different track settings. With up to 16 configurations per wheel, multiple track settings can be achieved to suit different row or bed widths, different tractors and axle details.

All Stocks adjustable centre wheels are designed with a 15mm thick, segmented, heavy duty steel flange (HDF) continuously welded on both sides into the rim to give reinforcement and eliminate point loads.

KEY FEATURES

-

High quality formed discs

-

Heavy duty 15mm flange

-

High quality - extremely tough rims

-

Available in sizes up to 54”

-

Manufactured to strict tolerances

-

Strong, heavy duty components and fixings

-

Any brand/any size of tyre

-

Colour matched paint

BENEFITS

-

Built to withstand high loads

-

Built for road and fieldwork

-

Versatile capabilities for different tramline widths

-

Replacement centre discs can be supplied with different hub details

-

Long term cost savings

-

Limit crop damage

FORMED DISC

Manufactured from 12mm or 15mm thick steel. Centre bores, stud holes and nut seats are precision machined to ensure a perfect fit to the tractor hub.

FLEXIBILITY

Up to 16 different adjustable configurations.

HEAVY DUTY FLANGE (HDF)

Wheels feature a 15mm thick HD steel flange (4 segments), continuously welded on both sides into the rim for reinforcement and to evenly distribute the load around the rim.

RIMS

Up to 8mm thick conforming to European Tyre and Rim Technical Organisation (ETRTO) standards built to your requirements.

SPACERS

18mm spacers as standard. 15, 10 and 5mm spacers also available.

HARDWARE

10.9 grade M16 high tensile, captive bolts and nuts, wheels up to 40” diameter use 8 bolts per wheel, and wheels from 42” to 54” diameter using 12 bolts.

WHY HEAVY DUTY FLANGE (HDF) ROW CROP WHEELS?

Row crop wheels are often subject to maximum loading, high road speeds and a hard ride due to higher tyre pressures. Stocks HDF wheels are designed to withstand the high loads imposed by large high speed tractors using front and rear mounted implements, and are manufactured to strict tolerances to ensure true running.

Heavy, high quality, formed discs are bolted to the flange with 10.9 grade M16 high tensile, captive bolts and nuts. Wheels up to 36” diameter use 8 bolts per wheel and wheels from 38” to 54” diameter use 12 bolts.

Spacers are supplied as standard to offer more track settings if fitted between the disc and the flange. HDF row crop wheels are available in all sizes up to 54” diameter.

VALVE GUARDS

On forestry and other specific wheels, Stocks can fit a variety of valve guards for optimum valve protection.

PAINT

All wheels are colour matched if requested and any paint type can be specified.

EVERY ENQUIRY BEGINS WITH TYRES

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp