HIGH OUTPUT, HIGH ACCURACY SEEDER-APPLICATOR SPREADS UP TO 15m

Stocks Ag have developed a new product line-up for its range of pneumatic applicators, able to spread seed and granules wider and at higher rates than ever before.

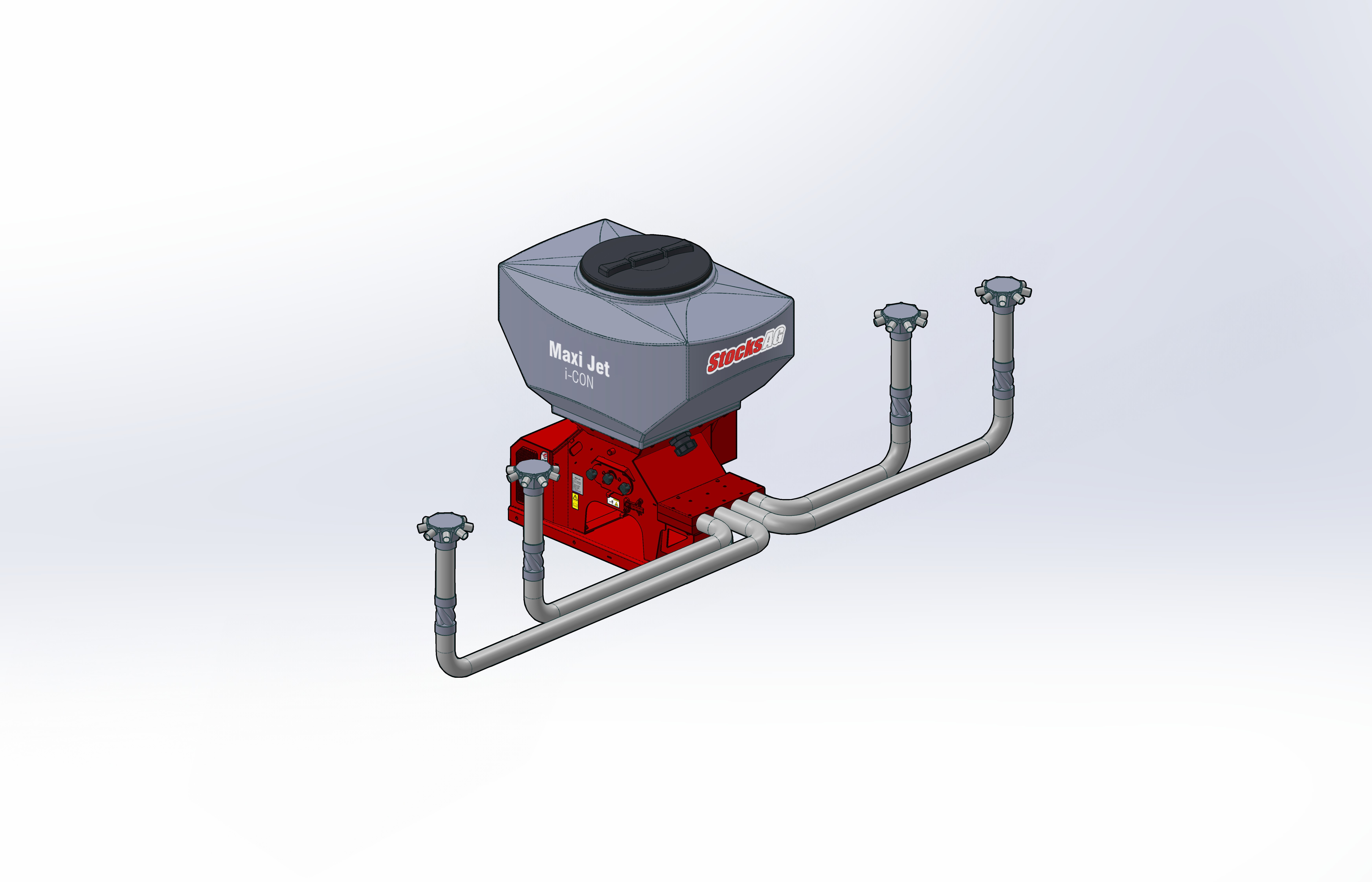

Launching at next month’s Agritechnica show in Hannover, Germany and complimenting the firm’s time-proven Turbo Jet range, the Maxi Jet is designed to distribute material out to working widths of 15m and at rates of between 1kg/ha and 200kg/ha.

One of the new machine’s key advantages is its versatility. It can be used to apply seed and granular products at extremely high rates of up to 200kg/ha on machines up to 6m wide. Alternatively, it can be used to spread material up to 15m at more conventional application rates, making it the widest-spreading Stocks applicator to date.

To achieve this extra output while maintaining a high level of precision, the design team at the Cambridgeshire-based manufacturer have had to come up with some innovative engineering solutions.

One of the key features of the new model is a move to the use of external distribution heads sited along the toolbar. This means the lengths of small-bore pipework are kept to a minimum with the result that airflow and material flow is constricted as little as possible.

With two- and four-outlet metering units available supplying the standard eight-outlet distribution heads, it is possible to have up to 32 spreader plates across the working width of whatever machine the applicator is fitted to. If more are required there is the option for larger bespoke distribution heads with up to 20 outlets each.

Generally, the two-outlet Maxi Jet 2 is recommended for working widths of up to 8m. Twin high-capacity electric fans are fitted as standard although there is the option of a hydraulically-driven unit. This is standard on the four-outlet Maxi Jet 4 which is designed for machines up to 15m wide.

Propelling material out to the furthest reaches of a 15m toolbar at the same rate as those in the middle of the machine presents a challenge and to ensure the product is evenly distributed the Stocks engineering team have come up with a novel innovation. Spiral risers are fitted within the 63mm supply hoses to the distribution heads that create a swirl effect in the airstream. This means material is evenly dispersed before it reaches the head with the result that there is a uniform supply to each of the eight outlets.

As with all Stocks applicators, fluted feed rollers are used to precisely meter material out of the hopper. New high-capacity rollers make it possible to handle large and small seeds at high rates and high application speeds.

Another of the Maxi Jet’s key attributes is that it can meter difficult flowing seeds at much lower rates. The feed roller can be configured to use just one segment to meter product to each secondary distribution head, it then dividing the flow to the delivery hoses and out to each of the spreader outlets.

Rates are automatically controlled in proportion to forward speed by Stock’s i-CON touchscreen monitor. Alternatively, the Maxi Jet can be managed by the tractor’s on-board ISOBUS controller. Variable application rates are also possible with a feed from a GPS control box.

You can find Stocks Ag at Agritechnica Hall 9, Stand H04 - Hannover Messe, Germany - 12-18th November 2023.

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp