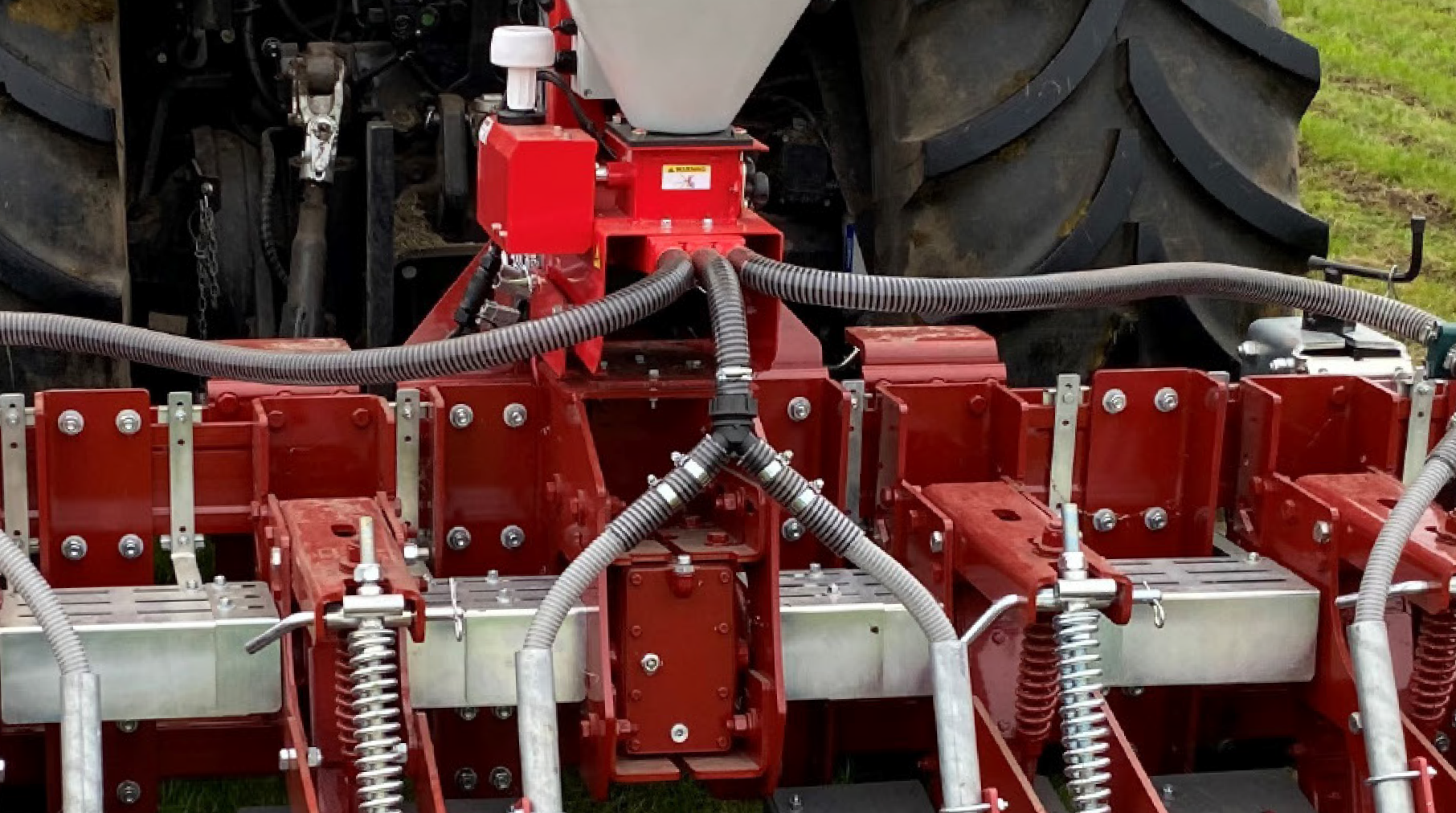

The Rotor Meter (gravity) and Rotor Meter Air Force (fan assisted) applicators are designed to accurately meter and apply seed or granules, ensuring a uniform application rate across the desired working width.

Typically integrated as additional applicators on drills and other planting machines, they can be specified with either single, double or triple outlets. The Rotor Meter is commonly mounted to potato planters to deliver sulphur granules and slug pellets. Alternatively, on salad or vegetable crops micro-granular fertiliser is often applied after establishment.

On grain drills, the Rotor Meter relies on a Venturi system to feed product (seed, granular products) into the pneumatic distribution circuit of the drill. As a stand-alone machine the Rotor Meter relies on gravity to spread product up to 1.5m. Several Rotor Meters can be fitted to host machines in series.

As a stand-alone machine the Rotor Meter Air Force has a spread width of up to 3.0m. (subject to product and application rate). The electric fan allows more flexibility in positioning the Rotor Meter Air Force on the host machine.

The Rotor Meter Air Force is frequently used for accurately spreading or effectively incorporating granular insecticides at narrow widths.

GRAVITY, METERED FEED

- ROTOR METER - up to 1.5m

AIR ASSISTED, METERED FEED

- ROTOR METER AIR FORCE - up to 3m

KEY FEATURES

- Metered feed roller system

- Rotor Meter is a gravity fed machine with 1, 2 or 3 outlets

- Rotor Meter Air Force is an electrically driven pneumatic fan machine with 1, 2 or 3 outlets (optional Y pieces on Air Force to give up to 6 outlets, max working width 3m)

- Air Force fan optional on Rotor Meter

- 65ltr or 130ltr semi-translucent polyethylene hopper

- Optional, GPS speed and variable rate control

- Choice of feed rollers

- Rotor Meter has a max working width of 1.5m

- Rotor Meter Air Force has a max working width of 3m, subject to application rate

For higher application rates, see our Turbo Jet range.

ROTOR METER CONTROLS

TWO CONTROL OPTIONS

A choice of either simple Vari-Speed (or Vari-Speed AF with fan speed control), or sophisticated i-CON control system that provides complete monitoring of the seeder/applicator.

Vari-Speed provides effective, low-cost, manually operated electric control. A dial control sets the feed motor speed and thus the application rate and this motor can be instantly started or stopped at headlands. Vari-Speed is not linked to forward speed so once calibrated the operator drives at a consistent forward speed to maintain the rate, or can manually increase or decrease application rates on the move using the dial.

VARI-SPEED CONTROL

- Left hand switch - feed motor on/off

- Centre switch - metering roller high/low speed

- Right hand dial - Metering roller speed control

VARI-SPEED AF CONTROL

- Left hand switch - fan on/off

- Left hand dial - fan speed control

- Right hand switch - feed motor on/off

- Right hand dial - Metering roller speed control

i-CON CONTROL

The primary function of the i-CON is to automatically maintain a pre-set target application rate as the forward speed varies, with on-the-move adjustment of the rate as required. The i-CON monitors forward speed via its own GPS sensor. Constant comparison and balancing of forward speed versus feed motor speed ensures an extremely accurate and reliable seeding rate is maintained.

- 4.3” colour touch screen with 4 basic menu keys

- Seed application rate kg/ha or seeds/m²

- Min/max forward speed (km/h) indicator with alarms

- Metering unit status (on/off) and alarm

- Fan status (on/off) and alarm on Air Force machines

- Hopper contents (kg) and low level alarm

- Part, full job and grand totals for area (ha), product dispensed (kg) and hours worked

- ISOBUS compatibility kit available

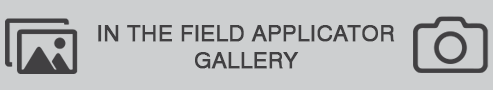

FLUTED FEED ROLLERS

Suitable for most products from ultra-low rate through to high rate applications, rollers agitate the product to ensure a consistent flow.

The speed of the feed roller is used to accurately control the rate at which the product is metered into the outlet(s).

A combination of 5mm small seed rollers, blank spacers and wide large seed rollers are used to build up the correct metering roller for the application rate required.

OUTLET SPREADER PLATES

The robust design of the spreader plates prevents any distortion and ensures a consistent even spread pattern.

Outlets are securely attached to a mounting rail and seed hose and removable bottom plates allow both band and broadcast sowing. Spreader plates are not included as standard, and are an optional extra.

Y CONNECTORS

Each of the three (max) machine outlets can be split into two using Y connectors. A single outlet machine becomes a twin outlet machine etc.

(Only recommended on Air Force machines). Y connectors are optional, therefore they are not supplied as standard.

AUTO SHUT-OFF SWITCH

A useful cut out switch shuts off the feed roller when the machine is lifted out of work on the headland. Supplied with i-CON, optional on Vari-Speed and Vari-Speed AF.

FITTING TO THE MACHINE

A simple base plate is supplied, and this allows mounting to the host machine from the bottom or back of the Rotor Meter.

CALIBRATION CHUTE

The optional steel chute is easily attached to collect the product into a user provided bag for weighing during calibration checks.

WATERPROOF COVERS

Rotor Meters can be supplied with an optional waterproof cover for protection when the machine is not being used.

ARABLE CROP APPLICATIONS

GROUND CARE APPLICATIONS

ROOT CROP APPLICATIONS

| ROTOR METER | ROTOR METER AIR FORCE | |||

| Control system | Vari-Speed | i-CON | Vari-Speed AF | i-CON |

| Electronic seed shaft monitoring | - | YES | - | YES |

| Electronic fan control | - | - | YES | YES |

| 12v fan speed monitoring | - | - | - | YES |

| Electronic adjustment of rate on the move | Manual | Auto | Manual | Auto |

| Fine and course feed rollers | YES | YES | YES | YES |

| Spreader/distributor outlets | 1,2 OR 3 | 1,2 OR 3 | 1,2 OR 3 | 1,2 OR 3 |

| Maximum number of outlets per meter | 3 | 3 | 6 | 6 |

| Maximum working width | 2m | 2m | 3m | 3m |

| Acoustic and visual warnings | - | YES | - | YES |

| Headland management - in/out of work switch | Option | YES | Option | YES |

| Area counter | - | YES | - | YES |

| Variable rate control with forward speed sensor | - | YES | - | YES |

| Electric fan | - | - | YES | YES |

| Hopper level sensor | - | YES | - | YES |

| Colour touch screen | - | YES | - | YES |

| GPS speed sensor | - | YES | - | YES |

| Control box cab mount | YES | YES | YES | YES |

| Hopper size (litre) | 65/130 | 65/130 | 65/130 | 65/130 |

Supplied with:

Vari-Speed

5m fused battery power cable and 6m connector cable are supplied as standard.

Extension cables are a cost option.

Power requirement:

12 volts DC – 15 amps

i-CON

7m fused battery power cable and 6m connector cable are supplied as standard.

Extension cables are a cost option.

Power requirement:

12 volts DC – 30 amps

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp