OVERVIEW

The Fan Jet range of applicators are cost effective and multi-purpose. Product is either gravity fed or metered onto a spinning disc for broadcast application. The spinning disc is driven by a 12v electric motor as standard. A choice of hopper size, spread width and mounting options are also available across all models.

Primarily used for slug pellet application, the Fan Jet is also an effective broadcaster of grass seed, other small seeds, granular products, game feed and even fish food!

All Fan Jet applicators share manual headland control functionality which is particularly important with chemical products, including slug pellets, to ensure product does not contaminate water courses or margins.

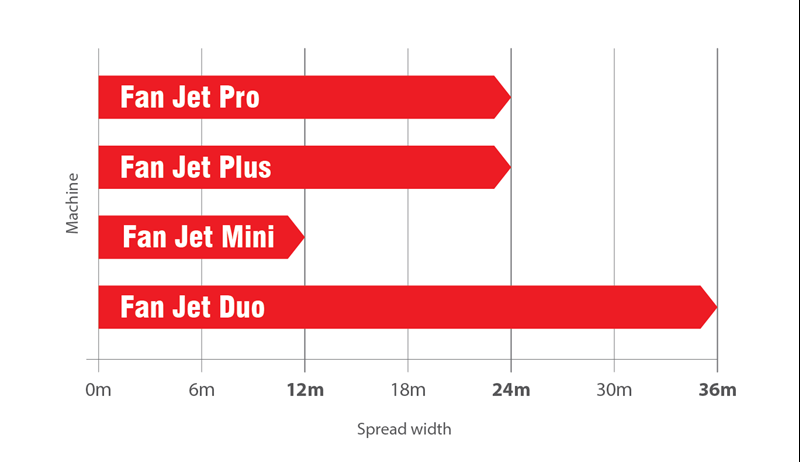

The table below compares all the applicators in the Fan Jet range.

N.B. Fan Jet maximum spread widths require full size slug pellets, correct disc height, correct power source and calm conditions.

Hopper capacity for slug pellets: 65 litre = 50kg, 130 litre = 100kg.

| FAN JET PRO | FAN JET PLUS | FAN JET MINI | FAN JET DUO | |||||

| Control system | Fixed Speed | Vario-Speed | Vari-Speed | i-CON | Vari-Speed | i-CON | VS-2 | TM |

| Single disc | YES | YES | YES | YES | YES | YES | - | - |

| Twin disc | - | - | - | - | - | - | YES | YES |

| Sliding plate (aperture) feed | YES | YES | - | - | - | - | - | - |

| Metered feed | - | - | YES | YES | YES | YES | YES | YES |

| Max spread width | 24m | 24m | 24m | 24m | 12m | 12m | 36m | 36m |

| Hopper capacity (litre) | 65/130 | 65/130 | 65/130 | 65/130 | 65/130 | 65/130 | 2 x 65/130 | 2 x 65/130 |

| Adjustable electric disc speed | - | YES | YES |

YES |

YES | YES | YES | YES |

| Automatic rate control with speed sensor | - | - | - | YES | - | YES | OPTION | YES |

| Electronic shutter control | YES | YES | N/A | N/A | N/A | N/A | N/A | N/A |

| Electronic metering feed roller control | - | - | YES | YES | YES | YES | YES | YES |

| Spread pattern bias adjustment | YES | YES | YES | YES | - | - | YES | YES |

| Acoustic and visual warnings | - | - | - | YES | - | YES | YES | YES |

| Boundary management | - | - | - | - | - | - | - | YES |

| Auto on/off via external sensor | - | - | - | YES | - | YES | OPTION | YES |

| Section control | - | - | - | - | - | - | - | YES |

| Hour counter & area counter | - | - | - | YES | - | YES | - | YES |

| Display of operating voltage & amps | - | - | - | YES | - | YES | - | YES |

| Colour touch screen | - | - | - | YES | - | YES | - | YES |

| Precision farming software capable | - | - | - | YES * | - | YES* | - | YES |

| GPS speed & hopper level sensor | - | - | - | YES | - | YES | OPTION | YES |

| Seed library (saved calibrations) | - | - | - | - | - | - | - | YES |

| USB flash drive updates | - | - | - | YES | - | YES | - | YES |

| Able to operate two units from one box | - | - | - | - | - | - | YES | YES |

Supplied with:

5m fused battery power cable and 6m connector cable are supplied as standard.

Extension cables are a cost option.

Power requirement:

12 volts DC – 20 amps. Except the DUO which is 60amp (2 x 30amp)

*licence fee required

BUILT IN THE UK

Wisbech is still the home of Stocks Ag. All applicators are fabricated, assembled and painted in the Cambridgeshire factory. Precision assembly and quality control are paramount to the production process.

The R & D team work with both the factory and farmers to deliver a seeding solution that is fit for current farming practices.

Share via WhatsApp

Share via WhatsApp